AG - Korrosion

"Korrosion unter Beobachtung, Schutz unter Kontrolle"

Grundlagenforschung und technologische Entwicklungen auf dem Gebiet der chemischen und mechanischen Korrosion verbessern das Verständnis der Korrosionsmechanismen. Die Forschung hat einen starken Einfluss auf die Entwicklung von Materialien mit verbesserten Korrosionseigenschaften.

Gregor Mori- AG Leiter Korrosion

Current projects

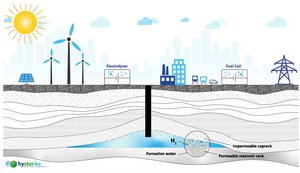

Pressure hydrogen attack on steels for underground gas storage

Abstract: In the framework of the EU project HyStories, the possibility of hydrogen storage in old gas reservoirs and underground gas storage facilities is investigated at several locations in the European Union.

In the course of this project, the Montanuniversitaet Leoben with the work package Materials and Corrosion has the task to evaluate the resistance to hydrogen embrittlement of selected pipe materials by autoclave testing under relevant conditions as well as to analyse hydrogen uptake and trapping behaviour by hydrogen permeation measurements and thermal desorption spectroscopy.

The following research questions arise in the context of this PhD thesis: Are the materials that are used in gas storage resistant to hydrogen embrittlement under the operating conditions which will occur? What are application limits? Why is a specific material more susceptible than others? What should be the microstructure of a material to increase its resistance to hydrogen embrittlement?

- Project funding: European Union´s Horizon 2020

- Project partners: GEOSTOCK SAS (GEOSTOCK SAS), France. Ludwig-Boelkow-Systemtechnik GmbH (LBST), Germany. CO2GEONET - RESEAU D'EXCELLENCE EUROPEEN SUR LE STOCKAGE GEOLOGIQUE DE CO2 (CO2GeoNet), France. MICRO PRO GMBH (MicroPro), Germany. FUNDACION PARA EL DESARROLLO DE LAS NUEVAS TECNOLOGIAS DEL HIDROGENO EN ARAGON (FHA), Spain. INSTYTUT GOSPODARKI SUROWCAMI MINERALNYMI I ENERGIA PAN (IGSMIE PAN), Poland.

- Project start: January 2021

- Project end: December 2022

- Project website:www.hystories.eu

Team-MUL: Bernd Loder; Masoud Moshtaghi; Gregor Mori

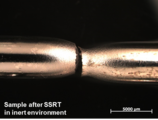

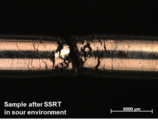

Abstract: Nowadays the oil-field development expands into deeper and more corrosive environment containing H2S, CO2 and brine at high temperature and high pressure, where materials should meet the criteria for corrosion resistance and mechanical properties. The required service life of such materials can be estimated and controlled by a standardized slow strain rate testing (SSRT) method, which proved to be quick and simple among other methods. Voestalpine BÖHLER Edelstahl GmbH & Co KG built up a laboratory for analysis of corrosion-resistant alloys (CRA) by SSR testing. In this work the development of SSRT method for environment stress corrosion cracking (SCC) as well as the verification of its results will be done. The testing procedure is developed in accordance with NACE standard TM0198-2016, where the samples undergo slow continuous strain at a constant extension rate until total failure in the simulated sour environment at elevated temperatures. The susceptibility of the material to stress corrosion cracking will be examined visually for evidence of brittle cracking and by measurement of the ductility parameters (reduction in area and plastic elongation) of sample tested in the sour environment compared with the sample tested in the inert environment.

Project funding: Third party funding

Project partners: voestalpine BÖHLER Edelstahl GmbH & Co KG

Project start: August 2019

Team: Anastasiia Galakhova, Werner Keppl, Andreas Schalli, Karl Prattes, Gregor Mori

Abstract: Corrosion resistant alloys for microbiological methanation applications are investigated in terms of hydrogen embrittlement. Constant load tests are performed in various atmospheres with up to 100 bar H2. The corresponding hydrogen absorption of steel specimens is measured, and the results are compared with those obtained after immersion in H2S-saturated solution.

Project funding: Third party funding

Project partners: voestalpine BÖHLER Edelstahl GmbH & Co KG

Project start: April 2019

Team:Anton Trautmann, Mathias Truschner, Josefine Pfeiffer, Andreas Keplinger, Gregor Mori

Publication(s): Trautmann, A., Mori, G., Siegl, W. et al. Berg Huettenmaenn Monatsh (2020) 165: 40.

Completed projects

Optimization of LPR Measurements under Oilfield Conditions

Corrosion problems in the oil industry occur in the different steps of production and storage processes. Consequently, corrosion is an important concern when tanks, equipment, and other steel components are used. The determination of the corrosion rate under certain conditions in specific environment is essential in predicting the service life of components. Several methods have been proposed to study corrosion processes: immersion tests with mass loss rate determination, electrical resistance testing, and electrochemical measurements. Electrochemical measurements can provide real-time and instantaneous information about tested species and therefore are subject to investigation for various applications in recent time. Linear polarization resistance technique meets all requirements and generating a detailed understanding on important methodological and technological parameters is the main objective of this research.

Electrochemical methodology shall be built up, validated and investigated to reproducibly determine corrosion rates under oilfield conditions. One aim is to optimize the test procedure (voltage, scan rate, deaeration time, duration of OCP measurement). In addition, several more parameters of interest will be investigated such as temperature, type and amount of inhibitor, surface condition etc.

- Project funding: OMV Exploration & Production GmbH

- Project partners: OMV Exploration & Production GmbH

- Project start: September 2021

- Project end: February 2022

- Project website: -

- Publications: -

Team-MUL: Magdalena Eskinja, Masoud Moshtaghi, Gregor Mori

STRACK

Abstract: The investigation of hydrogen influence on the material properties of steels is one of the major topics in modern steel research. Especially rail steels have very high demands regarding to the hydrogen content, which means in most cases amounts below 1 weight ppm.

Within the project STRACK fundamental research in the field of hydrogen charging, trapping, effusion and diffusion of rail steels, also with regard to different production steps and heat treatments is done. The project aims in broaden the knowledge and further develop material concepts for rail steels to prohibit hydrogen caused product failure.

Therefore rail steels will be electrolytic charged with hydrogen and their effusion behaviour is investigated as function of time. Furthermore, Thermal Desorption Spectroscopy (TDS) will be used to measure the total hydrogen uptake as well as to investigate the location of the hydrogen in the microstructure. Out of TDS results the binding energies for the materials different trap sites can be determined. Apart from this permeation measurements of various rail steels will be done to characterize hydrogen diffusion in rail steels. Additionally, all materials will be characterized with regard to their microstructure, grain size, precipitations and dislocation density by high resolution electron microscopy.

- Project funding: Österreichische Forschungsförderungs GmbH (FFG)

- Project partners: voestalpine Stahl Donawitz GmbH

- Project start: June 2020

- Project end: December 2022

- Project website:

- Publications:

- Team-MUL: Matthias Eichinger, Bernd Loder, Masoud Moshtaghi, Gregor Mori

- Team-Cooperating institutions:

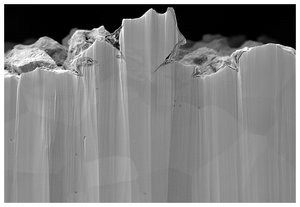

Urea corrosion

Abstract: Ferritic and austenitic stainless steels for urea industrial applications are investigated in terms of corrosion at high temperature. Corrosion tests are performed at the experimental test bench where injection of aqueous urea solution on the steel plate at high temperatures for different times took place. The test track and corrosion experiments are developed at the Augsburg University of Applied Sciences. The relationship between aqueous urea solution, its thermal decomposition products and the corrosion mechanism of stainless steel is studied by FTIR spectroscopy, SEM and stereo microscopy.

- Project funding: Third party funding

- Project partners: Faurecia Emissions Control Technologies; Augsburg University of Applied Sciences

- Project start: October 2020

- Team: Anastasiia Galakhova, Fabian Kadisch, Gregor Mori

Publication(s): Galakhova A, Kadisch F, Mori G, Heyder S, Wieser H, Sartory B, Burger S. Corrosion of Stainless Steel by Urea at High Temperature. Corrosion and Materials Degradation. 2021; 2(3):461-473. https://doi.org/10.3390/cmd2030024

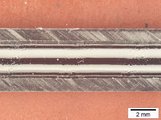

Stress corrosion cracking of high strength steel wire materials

Abstract: Oil production off the coast requires materials with the highest strength and resistance to stress corrosion cracking due to increasingly exposed wells. This project tests new materials in the field of low- and high-alloyed steels for such applications and optimizes these materials along the entire process chain to guarantee optimum safety for people and the environment.

- Project funding: Third party funding

- Project partners: voestalpine Wire Technology GmbH and voestalpine BÖHLER Edelstahl GmbH & Co KG

- Project start: December 2019

Team:Mathias Truschner, Gregor Mori

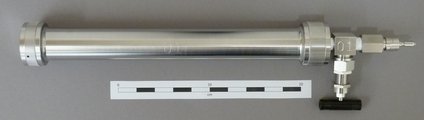

Abstract: The project aims in finding the optimal parameter setup for inside electropolishing of molybdenum tubes in order to the industries requirement of polishing tubes with the smallest inside diameter and as long as possible. Therefore electropolishing tests are operated under potentio- and galvanostatic conditions. Furthermore the effect of PCR (periodic current reversal) in the electropolishing process is investigated.

Project funding: Third party funding

Project partners: Plansee SE

Team: Matthias Eichinger, Gregor Mori, Bernhard Mayr-Schmölzer

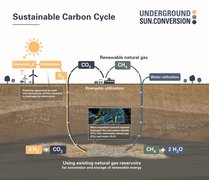

Underground Sun Conversion – WP 4 (Materials and Corrosion)

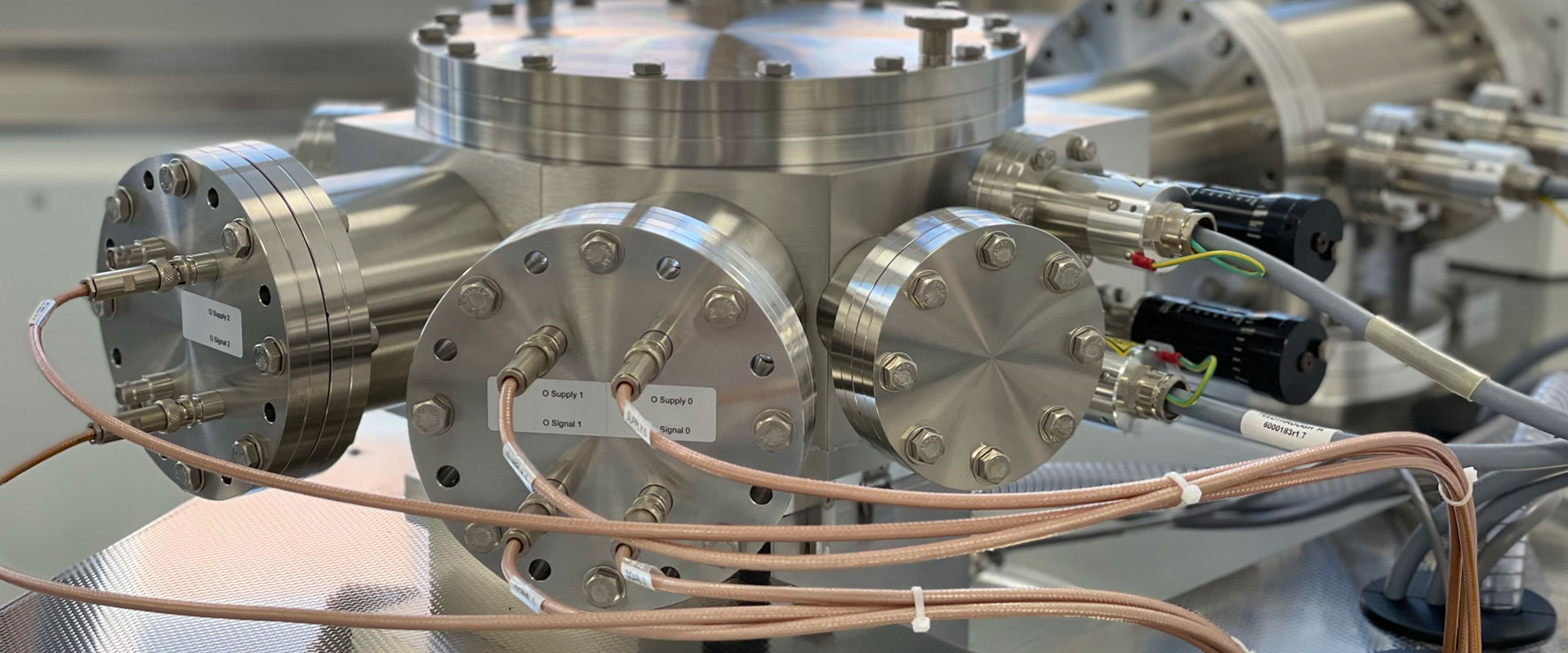

Abstract: Microbiological methanation is being investigated in an existing porous natural gas reservoir. Since H2 is involved in the process, the hydrogen embrittlement of steel must be considered. Therefore, a test routine was developed, and a unique autoclave test bench was designed to simulate field conditions. With this Hydrogen Embrittlement Autoclave Testbench (H.E.A.T.) different carbon steels were tested in up to 100 bar H2. Constant load tests (CLTs) were performed and the corrosion rate and hydrogen absorption of specimens were measured. A material recommendation for the equipment on site was given.

Project funding: Austrian Climate and Energy Fund (FFG project number 855231)

Project partners: RAG Austria AG, University of Natural Resources and Life Sciences (BOKU), acib GmbH, Energieinstitut an der Johannes Kepler Universität Linz, Axiom angewandte Prozesstechnik Ges.m.b.H.

Project start: April 2017

Team:Anton Trautmann, Mathias Truschner, Josefine Pfeiffer, Markus Oberndorfer, Gregor Mori

Publication(s): Trautmann, A., Oberndorfer, M., Mori, G., & Bauer, S. (2019, May 15). Susceptibility of Selected Steel Grades to Hydrogen Embrittlement - Simulating Field Conditions by Performing Laboratory Wheel Tests With Autoclaves. NACE International. https://onepetro.org/conference-paper/NACE-2019-13402

Project homepage:underground-sun-conversion.at

Druckwasserstoffuntersuchungen an Armco-Eisen und einer 30CrNiMo8-Legierung

Abstract: Es wurden Druckwasserstoff-Beladungsversuche im Autoklaven mit bis zu 100 bar PH2 an verschieden umgeformten und geglühten Armco-Eisen sowie an dem Vergütungsstahl 30CrNiMo8 durchgeführt. Es zeigt sich, dass ein höherer Umformgrad zu einer steigenden Wasserstoffbeladung führt. Temperatur und Zeit haben keinen großen Einfluss auf den Gesamtwasserstoffgehalt. Der Vergütungsstahl zeigt nur eine geringe Neigung zur Wasserstoffaufnahme. Langsamzugversuche am 30CrNiMo8 ergeben bei 10bar Wasserstoffdruck keine Neigung zur Versprödung.

Project funding: Third party funding

Project partners: Robert Bosch GmbH, voestalpine Tubulars GmbH & Co KG, voestalpine Stahl Donawitz GmbH, Materials Center Leoben Forschungs GmbH

Project start: Juli 2019

Team: Rüdiger Ruff, Wolfgang Siegl, Gregor Mori

Depassivation and Repassivation of Stainless Steels

Abstract: In oil and gas production, deep wells producing highly aggressive media are often completed with highly alloyed corrosion resistant alloys (CRAs, mainly steels). These CRAs have excellent corrosion properties due to the formation of a passive layer of chromium, iron and molybdenum oxides and hydroxides. During acidizing jobs, when a plugged well is re-opened, and during sand production at high flow velocities, localized or uniform depassivation can occur and yield high corrosion rates of used CRAs.

In the present work the resistance of passive layers of various stainless steels was investigated alongside the conditions and kinetics of when these layers are rebuilt. Methods applied consisted of: potentiodynamic experiments, immersion tests, scratch tests and variable pH flow experiments. Results revealed that, with the exception of those with very low alloys, all stainless steels showed repassivation after acidizing when the pH level increased above 3. Repassivation occurs within 100 s to a certain (sufficient) extent, although the passive layer is not completely rebuilt within this period.

Project funding: Third party funding

Project partners: OMV, ZAG (Slovenian National Building and Civil Engineering Institute)

Project start: August 2016